- +86-156 2426 6857

- amy@sdxxhg.com

UHMW Polyethylene has outstanding abrasion, wear, and impact resistance. UHMW is commonly

fabricated into conveyers, machine guards, and equipment housings.

Excellent wear resistance,good low temperature impact resistance,self-lubricating,non-toxic,water

and chemical resistance,heat resistance is better than general PE,the disadvantage is low heat resistance

(heat distortion temperature), processing and forming Poor,outer surface hardness,rigidity,creep resistance

is not as good as general engineering plastics,the expansion coefficient is too large.UHMWPE has poor

fluidity and high viscosity in molten state.It is a rubber-like high-viscosity elastomer.It can only be formed

by pressing and sintering at an early stage.It can also be processed by extrusion,injection molding and

blow molding.

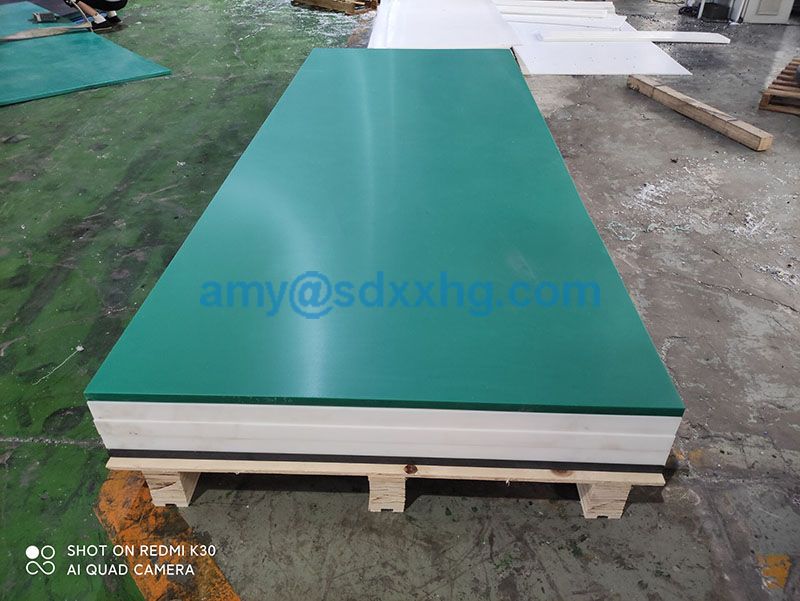

Materials:Reprocessed UHMW PE

Standard Size:1220*2440mm,4*8 ft

Processing Method:Mould Pressing

Thickness:8~200mm

Density:0.94g/cm3

Molecular Weight:6,000,000

Water Absorption Rate:<0.01%

Black UHMW Sheets Features:

Incredible high abrasion resistance and wear resistance;

Excellent impact resistance at low temperature;

Good self-lubricationg performance,non-adherent surface;

Unbreakable,good resilience,Super resistance of aging

Odorless,tateless,and nontoxic;

Extremely low moisture absorption;

Very low coefficient of friction;

Hightly resistant to corrosive chemicals except oxidixing acids.

Production Techniques And Equipment

Our uhmw sheets are made by moulding press,thickness 8~300mm.Comon full size of per

sheet is 4*8ft (1220*2440mm).We offer customize service,UHMW Sheets can be cut to any

size as customer's requirement.